Hot stamping machines

Hot stamping machine UT ECO

Machine for fast, accurate and uniform colouring of the embossed license plates utilizing a hot stamping method. The machine uses various colors of dying foils to coat the embossed design. The machine is equipped with the temperature regulator and it provides the possibility of the hot-stamping foil application in the temperature recommended by the hot- stamping foil manufacturers: 170 – 225 °C.

The hot-stamping machine UT-ECO uses less energy than similar machines of this type available on the market. The energy-saving technical solutions applied in the production of hot-stamping machines: special insulation of the drum, algorithm controlling the power supply of heaters, temperature control with an accuracy of 1 ° C, allow reducing the electricity consumption by more than 30%.

| Basic parameters |

|---|

| max. capacity: 360 plates per hour, |

| max. foiling width: 120 mm, |

| drum overheating protection, |

| small footprint, |

| power supply: ~ 230 V/50 Hz, |

| average power consumption 0.8 kW. |

| Options |

|---|

| “quick start” – reduced warm-up time approx. 6 min., |

| speed controller. |

Hot stamping machine DT ECO

DT ECO is an efficient and effective machine designed for the coating of embossed license plates, using hot stamping technology. It enables simultaneous coating of two single-row number plates as well as any other kind of number plate existing on the market. The machine is equipped with the temperature regulator and it provides the possibility of the hot-stamping foil application in the temperature recommended by the hot- stamping foil manufacturers: 170 – 225 °C.

The energy-saving technical solutions applied in the production of hot-stamping machines: special insulation of the drum, algorithm controlling the power supply of heaters, temperature control with an accuracy of 1 ° C, allow reducing the electricity consumption by more than 30%.

| Basic parameters |

|---|

| max. capacity: 850 plates per hour, |

| max. foiling width 235 mm, |

| speed controller, |

| foil tension control, |

| protection against overheating of the drum, |

| small footprint, |

| power supply: ~ 230 V/50 Hz, |

| average power consumption 1.0 kW (maximum power consumption 2 kW). |

Hot stamping machine MT ECO

An efficient and cost-effective machine for coating of embossed license plates by thermal transfer method. Specially designed for American dimension license plates.

The energy-saving technical solutions applied in the production of hot-stamping machines: special insulation of the drum, algorithm controlling the power supply of heaters, temperature control with an accuracy of 1 ° C, allow reducing the electricity consumption by more than 30%.

The machine is equipped with the temperature regulator and it provides the possibility of the hot-stamping foil application in the temperature recommended by the hot- stamping foil manufacturers: 170 – 225 °C. For the use of hot stamping machines UTAL offers high quality HP foil that ensures long-term durability of plates.

| Basic parameters |

|---|

| max. capacity: 360 plates per hour, |

| max. foiling width 180 mm, |

| speed controller, |

| foil tension control, |

| protection against overheating of the drum, |

| small footprint, |

| power supply: ~ 230 V/50 Hz, |

| average power consumption 1.0 kW. |

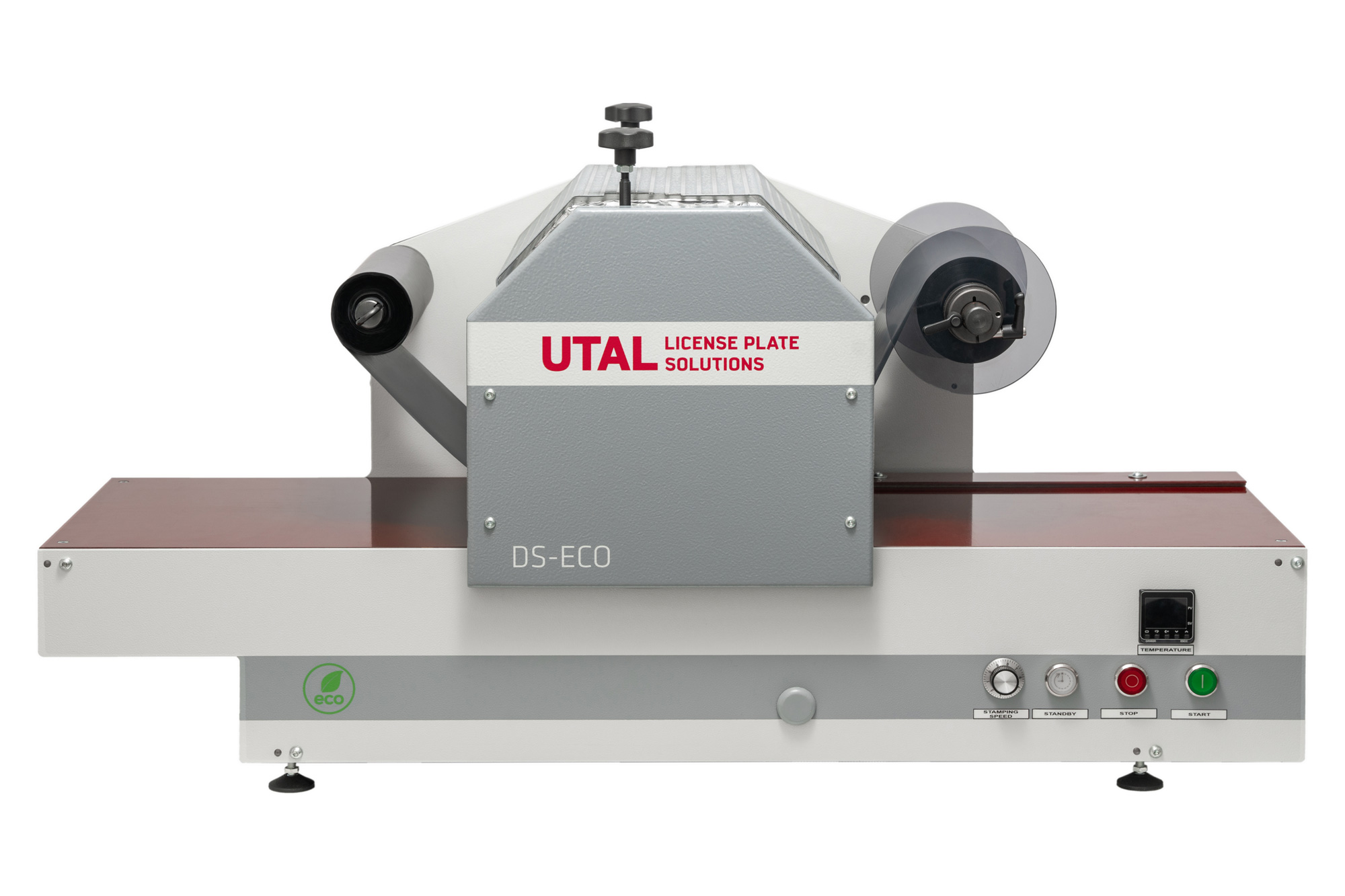

Hot stamping machine DS ECO

ENERGY SAVING. FAST. ERGONOMIC.

DS ECO is an efficient and cost – effective machine designed for the coating of embossed license plates, using hot stamping technology.

Thanks to the newly implemented solutions and modern design, this machine is a perfect choice not only for a serial type of production but also for the service points producing the license plates on request.

| Basic parameters |

|---|

| max. capacity: 850 plates per hour, |

| max. foiling width 235 mm, |

| speed controller, |

| foil tension control, |

| protection against overheating of the drum, |

| small footprint, |

| smaller and lighter construction – 108 kg, |

| power supply: ~ 230 V/50 Hz, |

| power consumption during steady operation 0,54 kW (power consumption in ECO mode 0,33 kW). |

| The main advantages of the machine: |

|---|

| ECO mode – after 5 min of inactivity, the machine comes into energy saving Stand By mode. This solution enables the significant reduction of the power consumption, |

| Quick heat up time – approximately 7 min (the time of heating up from the STAND BY temperature 120° to 200°) |

| Ergonomy improving solutions – automatic adjustment of the hot stamping drum position. Thanks to the license plate’s detection system, the hot-stamping drum automatically moves down to coat the embossed symbols. |

Hot-stamping machine DS ECO enables simultaneous coating of two single-row number plates as well as any other kind of number plate existing on the market. The machine is equipped with the temperature regulator and it provides the possibility of the hot-stamping foil application in the temperature recommended by the hot- stamping foil manufacturers: 170 – 225 °C.

The energy-saving technical solutions applied in the production of hot-stamping machines:

- NEW ECO mode,

- special insulation of the drum,

- algorithm controlling the power supply of heaters, temperature control with an accuracy of 1°C, allow reducing the electricity consumption by more than 30%.

UTAL © 2024

Created by B-MIND

ISO 9001:2015

ISO 27001:2017

ISO 14001:2015