Warning signs

Innovative solutions in the area of marking energetic infrastructure.

DESING AND PRODUCTION OF PLATES

| Our engineers from the Department of Technology and Development design the plates using a modern computer-aided 3D CAD design system. The plates are produced according to international standards (in compliance with ISO) and local (domestic) norms. The plates produced by the UTAL company fulfill all requirements of the most renowned European producers and distributors of energy. We are able to fulfill orders for individual companies according to their expectations in terms of a format, color or font. Our offer includes various types of plates in attractive prices and with very attractive terms of delivery. Thanks to mechanized and automated processes, we are able to produce up to 100.000 plates per day. Durable and practical plates with an RFID tags A transponder placed in the plates, also called an RFID tag, is the recognized standard for close communication used most frequently in reference to the industrial infrastructure. It has been implemented for many years in many countries. An RFID tag placed in the structure of the plates may contain information provided by the company using such marking. Data is read and modified using adapted devices and software. We provide sets of plates prepared for cooperation with GIS technology, including mobile applications used by the employees working outside. The line for the production of plates with an RFID tag is a modern technological solution allowing for automated and maintenance-free production. It is the fastest line available on the market, it allows for the production of about 900 plates per hour. |

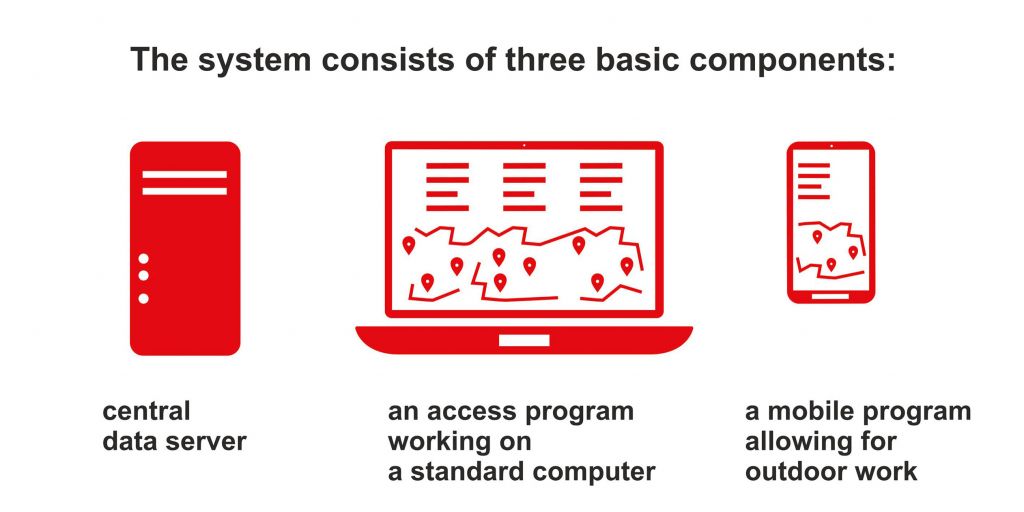

ASSEMBLY WITH THE USE OF GIS

A PLATE WITH AN RFID TAG

|

|

The RFID tag contain 693 bits:

unique number, date of assembly, object ownership information, object number, circuit number, links to other devices.

We manufacture in the following standards:

UTAL © 2024

Created by B-MIND

ISO 9001:2015

ISO 27001:2017

ISO 14001:2015